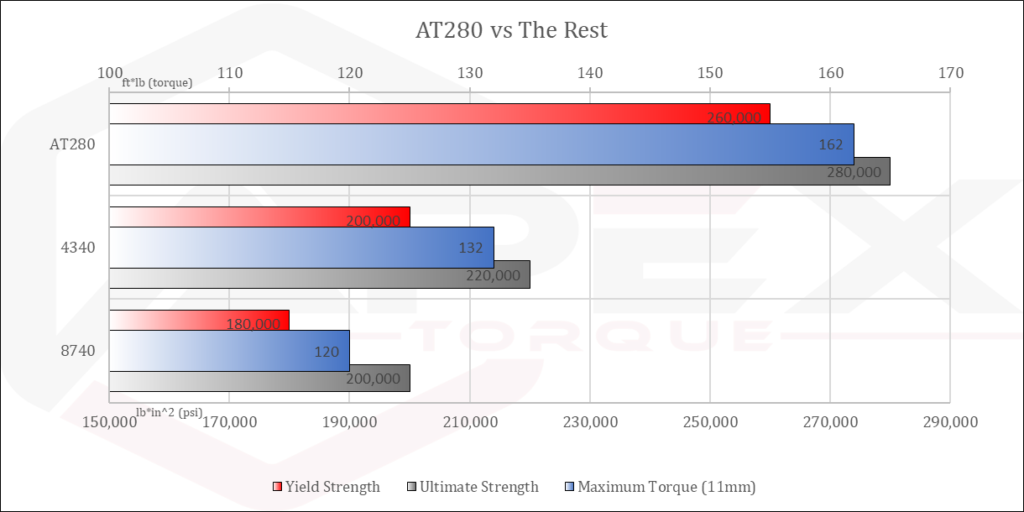

At Apex Torque we make the selection of your fasteners simple. We only manufacture fasteners from one alloy, AT280. This material provides high strength at 280,000 PSI Ultimate Tensile Strength and 260,000 PSI Yield strength. It has heat stability to 900°F, and when protected with our surface finishing process, will provide a 60-hour salt spray resistance to rust and an extreme scratch-resistant and low friction surface. With only the best available at Apex Torque, you don’t have to worry about which “alloy” to choose. It’s as perfect for getting the groceries as making 6-second passes at the drag strip.

History:

We developed AT280 over 6 months of testing different alloys and heat treatments. Our journey led us past 4000 series steel like 4340 and 8000 series steel like 8740 because of insufficient strength and heat instability. Tensile test after tensile test had us tweaking our heat treatment by 20°F at a time to find the perfect blend of strength and durability. When we found peak performance, we started branding it as AT280.

Performance and Value:

Our alloy in the market provides a high-performance fastener at an excellent value. You will likely find our studs comparable in price to the competitors’ much weaker products. That means there isn’t any reason to give you the racer the option to buy something “cheaper” from us. Instead, you get the same fastener on your weekend autocross car as a professional drifter \ drag racer \ road racer does on their 1500 horsepower engine. Our stronger products pay off because they can be reused over and over again without ever needing to “upgrade.”