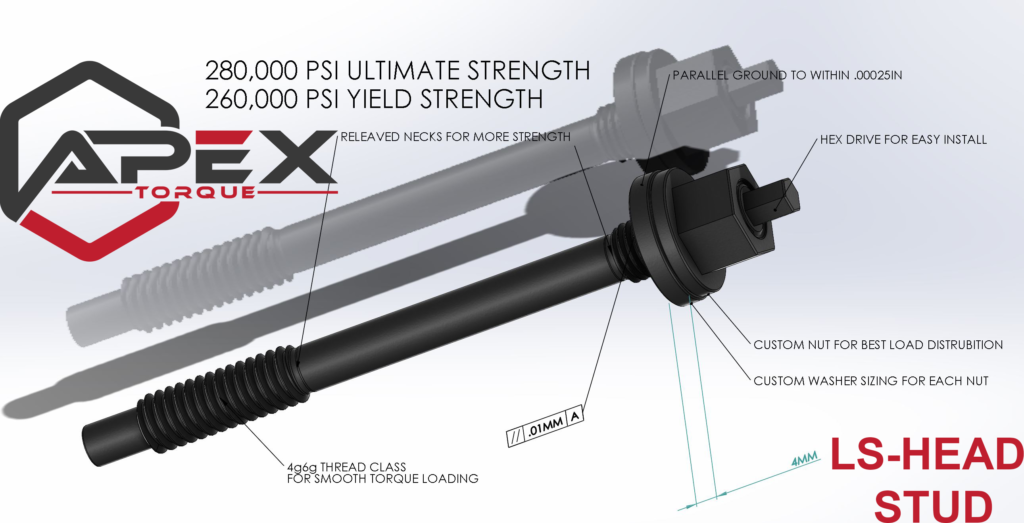

Every stud, nut, washer, and bolt are made from the purest, densest, and strongest form of steel – billet. Starting from billet means that everything is machined, and formed inside of a CNC machine in a single operation. This creates a part with accuracy and runout few can come close to. There is no hand rolling of fasteners, or moving from machine to machine that can cause tolerances and errors to stack up in the process.

Using CNC manufacturing for the fasteners allows us to perform a lot of tricks to get more performance out of the fasteners. We can make external hex heads for each assembly, neck backs on the threads to reduce stress, and because the CNC is so flexible the fasteners in each application are exactly matched to the engine for maximum performance.